Shinohara 79 Series

When Hans Gronhi announced the purchase of Japanese press manufacturer Shinohara in 2012, it signalled a new phase for the rising star of global offset. Established in 1919, the Shinohara name has always been associated with innovation at the cutting edge of press technology, a reputation Hans Gronhi is keen to maintain and expand upon. The acquisition also allows the values Hans Gronhi has become famous for - exceptional quality at a more affordable price - to be applied to the SRA2, B2 and B1 formats for the first time.

When Hans Gronhi announced the purchase of Japanese press manufacturer Shinohara in 2012, it signalled a new phase for the rising star of global offset. Established in 1919, the Shinohara name has always been associated with innovation at the cutting edge of press technology, a reputation Hans Gronhi is keen to maintain and expand upon. The acquisition also allows the values Hans Gronhi has become famous for - exceptional quality at a more affordable price - to be applied to the SRA2, B2 and B1 formats for the first time.

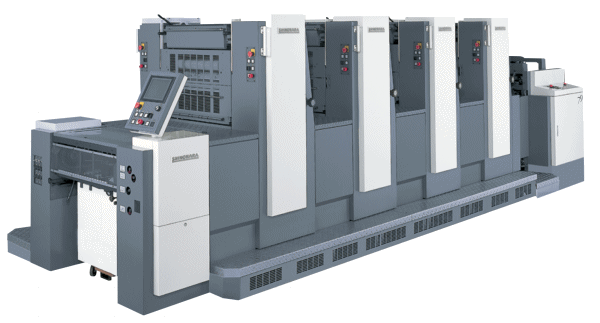

Shinohara presses are available in sheet sizes 66cm, 75cm, 79cm, 92cm with perfecting, mid and high pile options, and come with a host of other features, many unique within the Shinohara range.

The 79 series has a sheet size of 585 x 790mm and is

available in a wide range of configurations from four to eight colours, with medium and high pile options. It is also available as a perfecting machine.

Advanced Technology for Super Fast Make Readies, Productivity and Profitability!

-

Touch screen designed for interactive operation

A wide variety of tasks can be controlled using a touch screen designed to enhance operator efficiency. A modern intuitive interface also allows for the monitoring of settings during plate change or switchover to perfecting mode

Advanced Feeder Head

A redesigned feeder head meets the demands of high speed production, and means a minimum of adjustments are required when changing the sheet size.

High speed Registration system

Increased rigidity of the grippers is one of the factors which makes consistent registration at high speeds a key shinohara feature An ultrasonic double-sheet detector is used for monitoring misfed papers regardless of thickness or colour.

SPC (Shinohara Plate Changer)SPC offers semi automatic plate changing at the push of a button, and requires no plate bending or special tools, meaning operators can chnage plates quickly and precisely. Plate changeover takes less than a minute per unit.

Automatic cleaning systemsKeeping the blanket cylinders and ink rollers clean is integral to maintaining printing quality. Shinohara's automatic cleaning systems do the job in under a minute, at the push of a button.

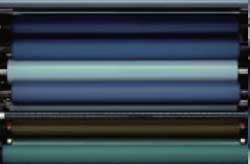

The optimal roller layout was designed to improve the efficiency of ink distribution. The SHinohara system achieves an ideal ink transfer and optimal ink/water balance.

Inking system with Optimal Water Balance

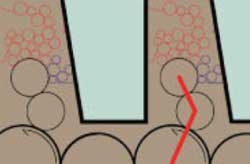

7 O'clock cylinder arrangementThe 7 o'clock cylinder arrangement (plate, blanket and impression cylinders) prevent gap shock marking, and ensures better ink distribution and ink film thickness

Accurate delivery controlShinohara's air blowers and sheet brakes function in an efficient manner, assuring proper paper delivery right down to the last printed sheet. Mechanisms such as front and side paper jogs assure consistent output. An optional built-in IR dryer can be applied to reduce time between production processes.