Shinohara Systems

For a full list of standard/optional features for the Shinohara range, clickhere

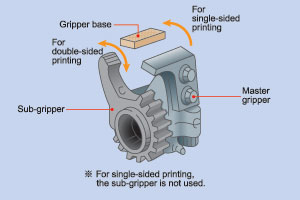

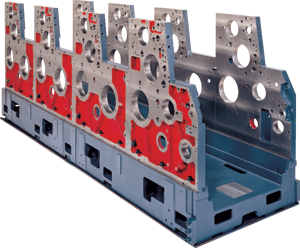

Shinohara perfecting system

One of the many examples of Shinohara's leading edge technology is the Shinohara Perfecting System, which has been developed and refined since it was first introduced in 1979. It incorporates many patented advances made by Shinohara and offers exceptional register accuracy. Changeover from straight printing to perfecting is quick and easy. |

|||

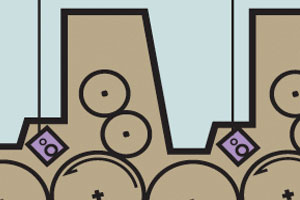

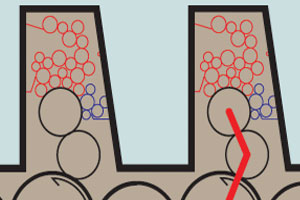

The most important factor in any perfecting system is its ability to control the tail edge of a sheet with one side already printed. This ensures that the sheet is guided properly to the next set of grippers. Shinohara employ a tail edge guide system to ensure superior register accuracy in the perfecting mechanism. The system is positioned around the double diameter storage drum so that it can wrap the sheet around the cylinder efficiently whilst applying tension to the sheet. Thanks to the guide system, the tail edge of the sheet is fed into the gripper properly every time, ensuring consistent paper transport and reliable accuracy every time. |

|

||

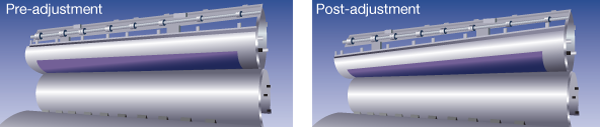

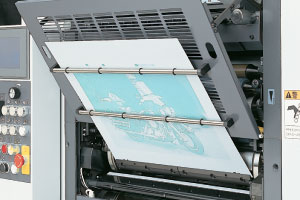

Plate cocking system with patented technology for excellent accuracyShinohara’s patented plate clamp cocking features a correlative system that enables fine adjustments to be made to plate registration without applying undue pressure to the plate. Plate registration can be adjusted during printing. The cocking adjustment range is up to 0.6mm. |

|||

|

SPC Shinohara Semi-Automatic Plate ChangerShinohara's SPC offers semi-automatic plate changing at the touch of a button, and requires no 90?bend and no tools, any operator can change plates quickly and precisely. Plate changeover takes less than a minute per unit. This speeds press makeready, increases press runtime and improves overall efficiency. |

||

|

|||

PRINT FOR PACKAGINGAn interdeck UV curing unit can be installed between printing units. The interdeck UV curing system reduces problems with trapping when UV/Hybrid inks are used. Since Shinohara presses utilize cold UV drying, they can also be used for special types of production, such as printing onto plastics. |

Automatic wash up systems

Keeping the blanket cylinders and ink rollers clean is integral to maintaining printing quality. Shinohara’s automatic cleaning systems complete the cleaning operations at the touch of a button.

Precise delivery control

Shinohara’s air blowers and sheet brakes ensure accurate paper delivery right down to the last printed sheet. An optional built-in infrared dryer can be installed to reduce time between production processes.

I

nk temperature control TCPS

Gives printers the ability to run at high speeds over many hours of continual production with consistent colour and print quality. The system utilises a series of water chilled rollers and is a factory fitted option.

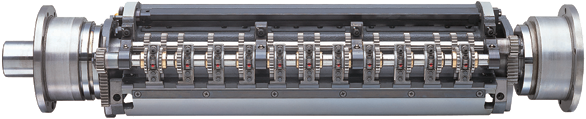

Registration system for high speeds

Superior rigidity of the grippers makes consistent registration at high speed possible from feeder through the transfer units, including perfecting and delivery.

Feeder head based on advanced technology

A feeder head that meets the need for high speed production, with minimal adjustments required when changing sheet size, ensuring faultless paper feed performance.

Pre set feeder and delivery option

Enter paper size and thickness, and the machine will automatically set various feeder and delivery positions, plus the appropriate impression cylinder adjustments.

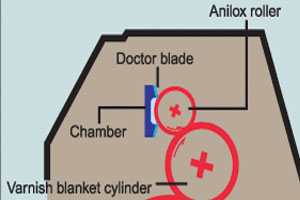

In-line coating unit

A chamber-type doctor blade creates an even layer of varnish on the sheet, assuring high quality coating. The unit also features automatic preparation and an automatic washing facility. The entire surface of the sheet can be coated, or a spot coating can be applied with a convex resin plate.

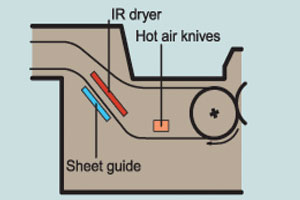

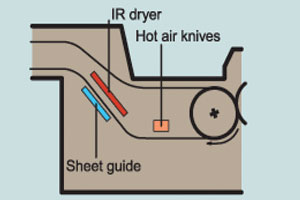

Drying systems

For presses with or without an aqueous coating unit, an infrared (IR) dryer in combination with a hot air knife can be installed in the delivery. For presses with a UV coating unit or UV printing application, a UV curing system can be installed in the delivery area and between printing units.

Cold UV curing system

Shinohara presses utilise cold UV drying. This highly effective drying system can be used during printing with UV/Hybrid type inks. This is very important when processing substrates that are sensitive to heat. Combination machines can be fitted with both UV and IR drying systems.

Interdeck UV curing unit

An interdeck UV curing unit can be installed between the printing units. This reduces problems with trapping when UV/hybrid inks are used. They can also be used for special types of production, eg plastic.

7 O’Clock cylinder arrangement

Shinohara presses (66/75/92) presses use a 7 o’clock cylinder alignment (plate, blanket and impression cylinders), preventing possible gap shock marking. It also assures better ink distribution and ink film thickness.