-

MKII hand feeder and crease

MKIII air feeder with crease / cross perfer module

MKIII Air feeder, creaser / cross perfer with remote folder (roll up fitment to many other brands)

Features

The modular bar creaser is the worlds first expandable bar creaser

You can start by buying the base manual unit, add the auto feed system, pump and stand later on

The creaser will handle most types of paper/card from 100 to 400 gsm

Feeding the manual feed unit is done by stacking the card in a single pile and feeding successively the sheets

Feeding by the auto feeder can be done continuously loading the pile

Setting up the machine is done by the easy to use LCD screen where all the main parameters for can be loaded in seconds

Large reception tray with magnetic stops

Jam detector

JDF future compatible

Touch screen control

The creaser can optionally be fitted with perfing wheels mounted on the output shafts

Optional perfing wheels on the outfeed

Optional infeed tray extension for sheets up to 600 mm long

Technical menu

QWERTY keyboard for naming programs

-

Modular Finishing System

Unique in the world:

The only system that uses a common set of finishing modules to create a upgradable machine that can fill all your finishing requirements in 1 pass. You can grow the system as your budget permits and add modules at will.

The unique open architecture of the MFS is being constantly upgraded, new modules are being developed continually to fill even more of your finishing needs using the existing base modules.

Why buy a fixed configuration machine that you will have to throw away when your needs grow/ change? Donít throw away your money! Get the only expandable machine that will always let you grow!

Contact Sales at Printers Superstore for More Information

Technical Specifications

Creasing / Cross Perfing Module

Creasing direction up or down depending on the blade installation

Sheet processing time: Ca. 1 sec per a4 sheet l.e.f with 1st crease 15 mm from lead edge and last crease 2 mm from tail edge.

Creasing / perfing action: Ca. 2 crease / sec if closely spaced

Min. spacing 0.3 mm

Crease / perf per sheet 1 to 16

Min infeed length (advisory) 120 mm

Min. nr. of crease per sheet 0 (bypass function)

Skew compensation

Blade is modular and can be changed in a few minutes

Optional perfing wheels on the outfeed shafts, easy to fit split holders no disassembly required, 1 to (!) 4 sets

Tool-less connection to feeder unit

Size 20cm x 45 cm x 45 cm

Weight Ca. 25 kg

Power supply 300w

Card Thickness 0.1 to 0.4 mm

Selection of slide in tools: Narrow blade / wide blade / double action ++ blade / double action +- blade

perfing blade 24TPI full width /3/4 width /2/3 width /1/2 width /1/4 width.

Feeder unit module

Shingle hand feed or Suction bottom feed

Card types from 100 to 400 gsm

Min. length Ca. 150 mm

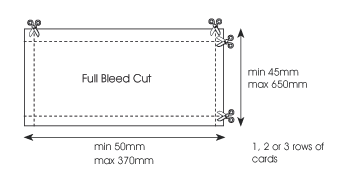

Max. length 650 mm air feed / 900 mm hand feeding

Min. width Ca. 120 mm for auto feed (less on hand feeding)

Max. width 370 mm (full Igen size) or 330 mm (narrow version)

Pile height To max 4 cm depending on paper type and size

Adjustable paper separator in 2 dimensions

Adjustable general air blast and individual orifices

Adjustable air suction angle

Adjustable feed frequency

Registration belt

Stop and start feeding to reduce sheet rubbing

Feed roller with extra sticky rubber rings and radial plenums for better paper grip

Weight Ca. 25 kg

Size Ca. 70cm x 45 cm x 45 cm

Power (without pump) 220 V, 50 Hz, 300 W

Pump module Ca. 40 kg, 70cm x 50cm x 50cm

Quietest operation in its class, reduced compressor noise, reduced noise from the suction roller. Highest quality dual stage compressor with separate circuits for suction and compression, almost no heat in the compressed air, which means better sheet separation.

Power supply from feeder module 1500 W

Stand with 4 lockable wheels

Control panel module

Normally located on the feeder module

LCD touch screen for all functions

92 nameable memories

2 speeds

Technical menu

Several language options

Software expandable to accept other modules later on Japanese electronic components and only 1 main board

Adjustable contrast

Delivered with protective plastic film

Just 3 touches to needed to get started

Power: 12v dc 25 w from feeder power supply

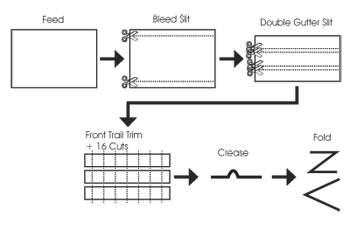

Folder unit module 2

Folder accessory: Equipped with its own control system for on or near line use.

Equipped with programmable step output conveyor and bypass tray. Fold roller spacing with digital readout.

1 or 2 folds or bypass

Adjustable fold roller spacing

Adjustable knife timing

Length min fold 70 mm

Length max fold 490 mm on single fold

Min infeed size (advisory) A5 SEF

Widths Min. and Max. as per feeder

Max weight for single fold Ca. 350 gsm

Max weight for double fold Ca. 300 gsm

Min weight advisory Ca. 100 gsm

Paper Thickness 0.35mm

skew adjustment compensation

Tool-less connection for creaser module or feeder unit

Module weight Ca. 45 kg

Size Ca. 40 cm x 40 cm x 55 cm

Power 220 V, 50hz, 450 W, from feeder unit

Folder can be used:

Attached to directly to creaser / perf module

Or: On line via register conveyor infeed

Or: Near line hand feeding

Or: On line behind certain other makers creasers via register conveyor infeed