-

Technical Specifications

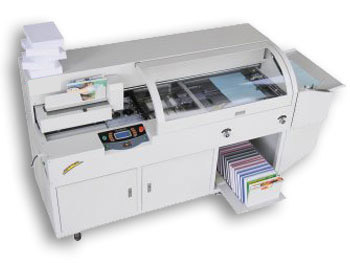

Perfect Binder

Length refers to spine length, height refers to book width

Book size min 130 length x 140 mm height

Book size max 420 length x 320 mm height

Binding thickness 2 mm to 58* mm

Cover sizes min 135 length x 260 width

Cover size max 420 length x 660 width

Cover weights min 120 gsm max 300 gsm

Mechanical cycles/hr 450+

Warm up time approx 30 min

Milling and slitting, adjustable height, using shims

Signature milling to 3 folds

Cover clamp automatic setting and process

Book clamp automatic setting and process

Glue application 2 rollers and one reverse scraper roller

Side gluing self adjusting to book thickness using separate glue tank

Glue cut off self adjusts to the cover length

Display LCD computer controlled

Cover clamp adjustable in height and side clamping force

Cover position compensation by computer

Cover feeder by suction roller 5 cm pile height

Soft book ejection slide with book reception container

Fully guarded

Extra cover tray

Metric/Imperial size switch over

Adjustable glue application speed

Dimensions 2500 x 785 (+350 for book stacker) x 1245

Weight 600 kg

Consumption 3500W single phase

Fume extractor

Chip and waste extractor with waste bag outside the machine

Padding to 58 mm and milling to 50 mm on low speed with 1mm cut depth

• Certain very heavy card stocks may need to be pre creased for best results

• Production speed varies with book size, thickness, glue, stock, covers used, and other environmental factors

(* Thick books 20 mm + on low speed with 1 mm milling)

****specifications subject to change without notice, errors and omissions excepted****

-

Fully Automatic Binder

The fully automatic binder is the result of evolution of a hand fed binder, coupled with a fully automatic cover feeder.

The binder has a compact size, pleasing design, and the most advanced features to be found on any single clamp binder at any price.

Fully self setting for book thickness and length and is thus perfectly suited to variable data production and quick production runs Production rates of over 450 cycles per hour are possible.

Contact Sales at Printers Superstore for More Information

Features

Fully Automatic binding cycle coupled with loading station

Fully automatic cover feeder using suction roller feeding

Extra cover storage tray near cover station

Binding widths to 5.8 cm

Automatic book ejection

Automatic book high capacity stacker

Two application rollers and one scraper roller

Separate glue tank for side gluing just like on 10 clamp machines allows the use of specific fast drying glue for the cover wraparound

Adjustable glue height

Programmable machine settings for all major functions

Program memories

High power milling unit with patented milling head

Heavy duty book slitting

High capacity chip extractor with separate turbine and large waste bag

Cover creasing using soft nylon rollers for gently creasing the cover

Patented cover pressing system for ultra square backs

Programmable clamping force and time

Self adjusting side gluing

Self adjusting total process for book thickness, perfect for book for 1 and variable data books runs

Self adjusting process for book length

Self inputting cover size data

High definition computer controlled display

Glue cut off on front and back of book used on both applicator and spreader rolls

Self adjusting book gluing speed optimized to book thickness

Padding mode

Fully enclosed with fume extractor

Mobile on casters

Small in size and not to heavy to be moved to where needed

Fully self diagnostic for error tracing